FANGCUNDA uniquely combines in-house Parylene dimer material expertise with advanced coating equipment engineering.

From proprietary Parylene powders to optimized CVD system design, FANGCUNDA delivers stable, production-ready coating solutions that ensure consistency, reliability, and superior coating performance.

1. Strong Technical Team with Multidisciplinary Expertise

FANGCUNDA’s technical team consists of graduates from leading Chinese universities with backgrounds in chemistry and mechanical engineering. This solid theoretical foundation enables precise integration between Parylene materials and coating equipment. The team covers the entire workflow, including electrical control, mechanical design, supply chain management, system commissioning, and after-sales support, ensuring equipment stability and process reliability.

2. In-house R&D and Manufacturing of a Full Range of Parylene Powders

FANGCUNDA offers the most comprehensive portfolio of Parylene powder materials, all independently developed and manufactured in-house. This unique advantage allows us to gain deeper insight into the material properties, processing characteristics, and application requirements of different Parylene types, supported by extensive market and application experience across multiple industries.

3. Enabling High-Performance Parylene Coating Processes

Leveraging our in-depth understanding of Parylene chemistry and coating equipment, FANGCUNDA designs systems based on the fundamental working principles of each stage of the Parylene chemical vapor deposition (CVD) process. As a result, we deliver high-performance Parylene coating equipment that is closely aligned with real-world coating processes and evolving market demands, helping customers achieve consistent and reliable coating quality.

• Automated Control & Smart Data Management

Precise control of coating parameters ensures stable processes and consistent coating quality. Fully automated operation supports real-time monitoring, data recording, waveform visualization, and secure multi-level user access.

• High Precision & Process Stability

A dynamic chamber design and advanced pressure control deliver excellent coating uniformity and repeatable performance. High-accuracy vacuum measurement with optimized system architecture extends component service life.

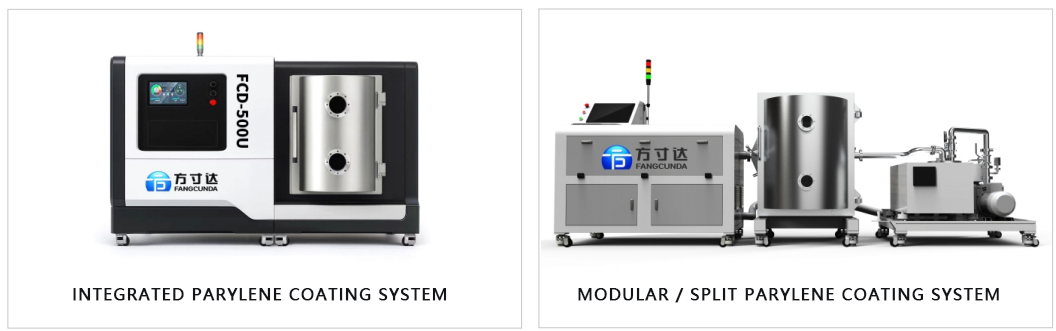

• Flexible Models & Customization

A complete range of system models supports different materials, production scales, and application requirements, with customization available to meet specific process needs.

• Easy Maintenance & Energy Efficiency

Maintenance-friendly design simplifies operation and servicing, while optimized system structures reduce energy consumption and operating costs.

Contact Us to Get the Parylene Coating Equipment Brochure

Do you have a question and would you like to get in touch with our experts? We look foward to receiving your inquiry!