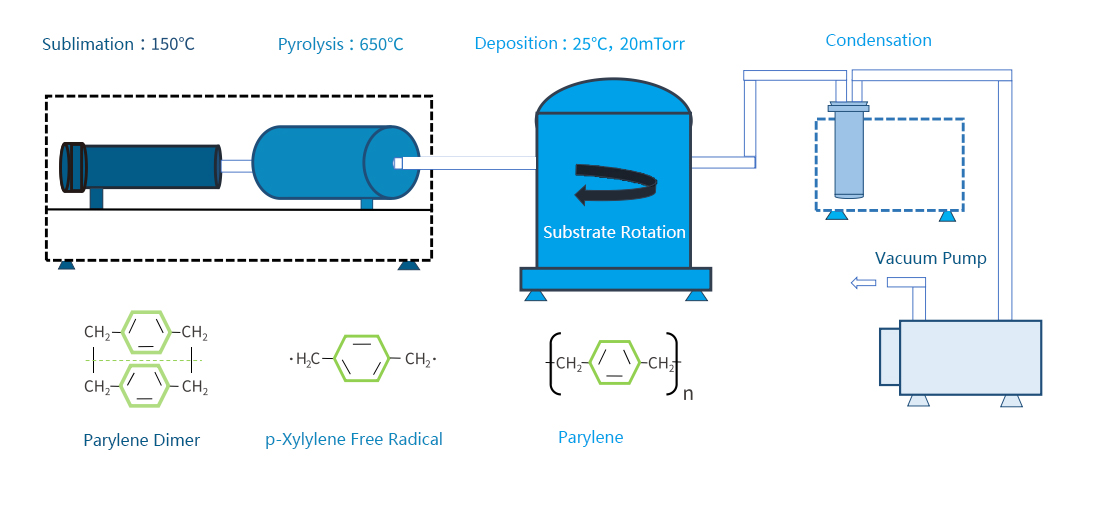

• Sublimation: Solid Parylene feedstock absorbs heat and sublimates in the vaporization chamber.

• Pyrolysis: The sublimated vapor enters the pyrolysis chamber, where it is thermally cracked at high temperature to form reactive monomers.

• Deposition: The reactive monomers are then transported into a room-temperature vacuum deposition chamber, where they deposit and polymerize on the surface of the parts, forming a dense and conformal Parylene protective coating.

궁금한 점이 있으신데 전문가에게 문의하고 싶으신가요? 여러분의 문의를 기다리겠습니다!